I broke out the random orbital sander and smoothed out the edges of the glazing putty I had laid down. Once I was satisfied with the result, I applied another coat of the urethane primer over the entire roof. The results were pretty nice, as I now had a perfectly etched surface on which to apply the liquid roof.

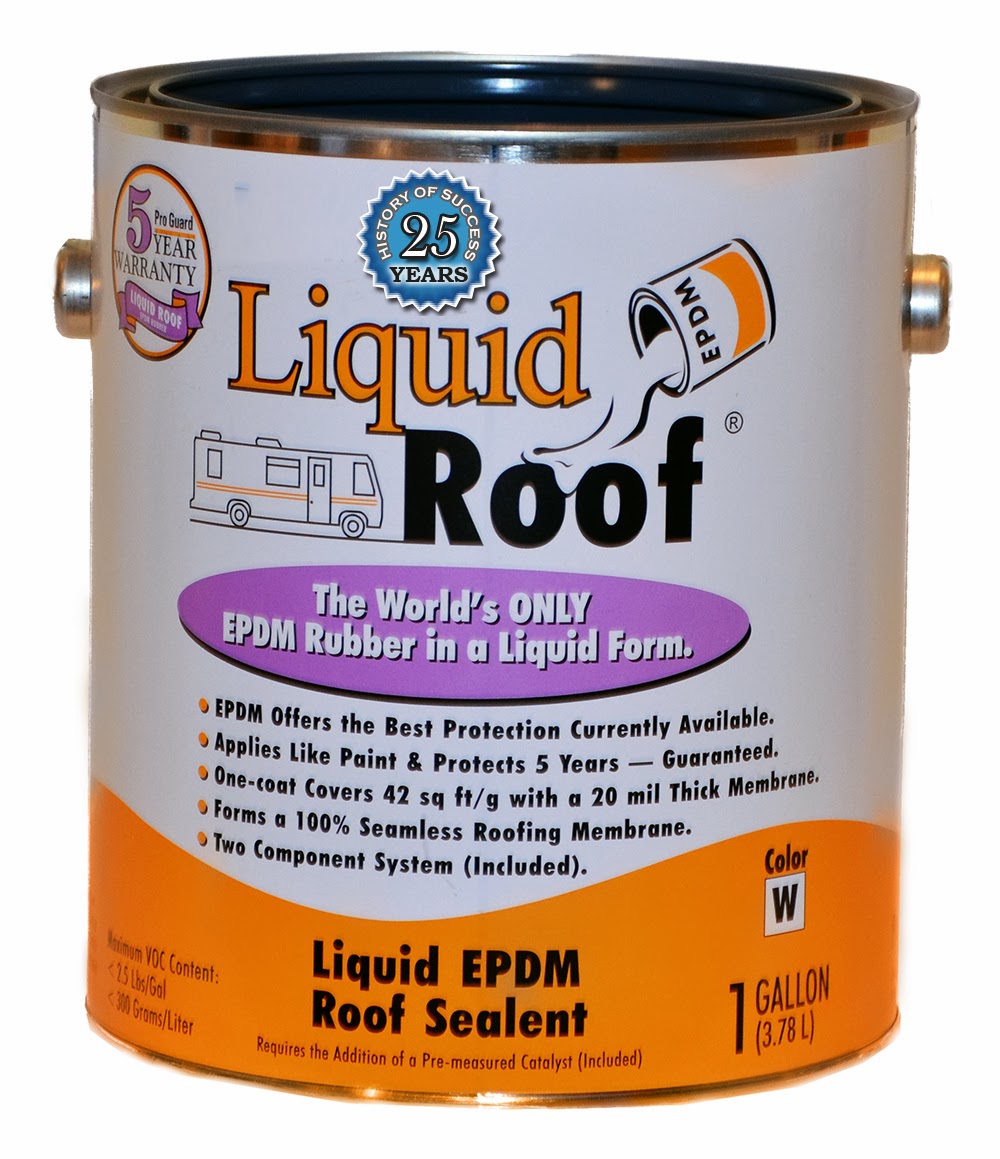

Everything I had read about mixing and using liquid roof had indicated how difficult a material it is with to work. They were all wrong.

It is nearly IMPOSSIBLE.

This product should be renamed White Tar.

I started by attempting to apply thin coats around the edges of the Air Conditioner port. It spread like frozen molasses. By the time I had worked around the edges, it switched to the "pour and spread" application method.

I attempted to spread it along the top of the roof with a squeegee, but this proved impossible as well. I finally broked out the paint rollers and rolled the material from every angle along all the exposed surface I could find, going back and touching up the bottom edges of the roof with brushes.

I have to say, the first coat results look pretty impressive. The material is supposed to be self settling, though I am not sure exactly how long that is supposed to take as results vary with ambient temperatures.

From every angle, this first coat does look pretty promising, so I left the camper in the garage to dry over the next few days. The covered storage should help in keeping any loose dust, twings, and insects off the roof while it cured.

Knowing that I would be waiting a while during the week, I chose to find a something small to redo in the camper.

The sink has a wood cutting board that goes over it. From the looks of the wood, it has been neglected over the years and never maintained.

I decided to oil up the wood to try and keep it from drying out. In this case, a little lemon oil should hopefully do the trick.

Over a period of days, I applied several coats of lemon oil to the wood, allowing for the cutting board to soak it up and bring out the grain texture.

I will keep applying layers until it darkens up to somewhere near an antique oak color. Over the next few days I will keep checking on the roof to see the results, and hopefully some more good weather will open up for me to lay down a second coat of the liquid roof.

More to come..